- Benefits of Laser Cleaning for Concrete Surfaces

- How Laser Cleaning Works on Concrete Contaminants

- Comparison of Laser Cleaning vs. Traditional Cleaning Methods for Concrete

- Case Studies of Laser Cleaning Success on Concrete Surfaces

- Safety Considerations for Laser Cleaning Concrete

Benefits of Laser Cleaning for Concrete Surfaces

1. Precision Cleaning

Laser cleaning uses a focused beam of light to remove contaminants from the surface of concrete without damaging the underlying material. This precision cleaning process allows for targeted removal of dirt, grime, paint, or other substances without affecting the integrity of the concrete surface. The laser can be adjusted to different power levels and speeds to achieve the desired cleaning results, making it a versatile and effective cleaning method for concrete surfaces.

2. Environmentally Friendly

Unlike traditional cleaning methods that rely on harsh chemicals or abrasive materials, laser cleaning is an environmentally friendly process that does not produce any waste or harmful byproducts. The laser beam vaporizes contaminants on the surface of the concrete, leaving behind a clean and residue-free surface. This eco-friendly cleaning method is safe for both the environment and the workers performing the cleaning, making it a sustainable choice for concrete surface maintenance.

3. Cost-Effective

Although laser cleaning technology may have a higher upfront cost compared to traditional cleaning methods, it offers long-term cost savings due to its efficiency and effectiveness. Laser cleaning requires less labor and time compared to manual cleaning methods, reducing overall cleaning costs and increasing productivity. Additionally, the precision cleaning capabilities of laser technology can extend the lifespan of concrete surfaces, reducing the need for frequent maintenance and repairs.

4. Non-Destructive Cleaning

One of the key benefits of laser cleaning for concrete surfaces is its non-destructive nature. Unlike abrasive cleaning methods that can damage the surface of the concrete, laser cleaning gently removes contaminants without causing any physical damage. This non-destructive cleaning process preserves the integrity and appearance of the concrete surface, ensuring that it remains in good condition for years to come.

5. Versatile Applications

Laser cleaning technology can be used for a wide range of applications on concrete surfaces, including removing graffiti, paint, rust, oil stains, and other contaminants. The versatility of laser cleaning allows for customized cleaning solutions for different types of concrete surfaces, from floors and walls to bridges and monuments. Whether you need to clean a small area or a large surface, laser cleaning can provide efficient and effective results for all your concrete cleaning needs.

6. Improved Safety

Traditional cleaning methods such as pressure washing or chemical cleaning can pose safety risks to workers due to the use of hazardous chemicals or high-pressure equipment. Laser cleaning eliminates these safety concerns by using a non-contact cleaning process that does not require the use of chemicals or abrasive materials. This reduces the risk of accidents and injuries during the cleaning process, creating a safer working environment for cleaning crews.

7. Enhanced Aesthetics

Dirty or stained concrete surfaces can detract from the overall appearance of a building or structure. Laser cleaning can restore the original appearance of concrete surfaces by removing unsightly contaminants and restoring the natural color and texture of the concrete. This enhanced aesthetic appeal can improve the overall look of a property, making it more attractive to visitors, customers, or residents.

8. Minimal Disruption

Laser cleaning is a quick and efficient cleaning method that minimizes disruption to daily operations or activities. The non-invasive nature of laser cleaning allows for cleaning to be performed in occupied spaces without the need for extensive preparation or downtime. This minimizes disruptions to business operations or public access, allowing for efficient cleaning of concrete surfaces with minimal impact on daily activities.

9. Long-lasting Results

Unlike traditional cleaning methods that may provide temporary results, laser cleaning offers long-lasting cleaning results for concrete surfaces. The precision cleaning capabilities of laser technology ensure that contaminants are completely removed from the surface, preventing them from reappearing in the future. This long-lasting cleaning solution can help maintain the appearance and integrity of concrete surfaces for an extended period, reducing the need for frequent cleaning or maintenance.

10. Easy Maintenance

Once concrete surfaces have been cleaned using laser technology, they require minimal maintenance to keep them looking clean and well-maintained. The non-destructive nature of laser cleaning ensures that the surface remains in good condition, reducing the need for frequent cleaning or repairs. Regular inspections and routine maintenance can help prolong the lifespan of concrete surfaces and ensure that they continue to look their best for years to come.

Conclusion

Laser cleaning offers a range of benefits for cleaning concrete surfaces, including precision cleaning, environmental friendliness, cost-effectiveness, non-destructive cleaning, versatile applications, improved safety, enhanced aesthetics, minimal disruption, long-lasting results, and easy maintenance. Whether you need to remove graffiti, paint, oil stains, or other contaminants from concrete surfaces, laser cleaning provides an efficient and effective cleaning solution that preserves the integrity and appearance of the concrete. Consider using laser cleaning technology for your next concrete cleaning project to experience the many benefits it has to offer.

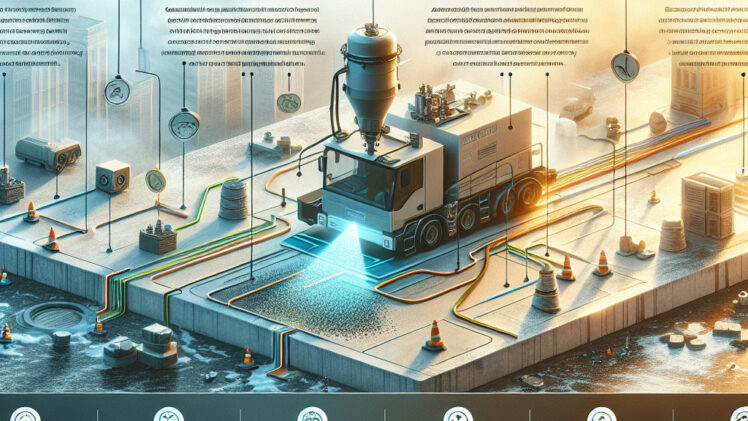

How Laser Cleaning Works on Concrete Contaminants

How Laser Cleaning Works

The laser cleaning process works by focusing a high-energy laser beam onto the surface of the concrete. The laser beam heats up and vaporizes the contaminants, causing them to be removed from the surface. The laser beam can be adjusted to different power levels and pulse durations to effectively remove different types of contaminants.

One of the key advantages of laser cleaning is that it is a non-contact method, meaning that there is no physical contact between the laser and the surface being cleaned. This helps to prevent damage to the concrete surface and allows for precise control over the cleaning process.

Benefits of Laser Cleaning

There are several benefits to using laser cleaning for removing contaminants from concrete surfaces. Some of the key benefits include:

| Benefit | Description |

|---|---|

| Efficiency | Laser cleaning is a fast and efficient method for removing contaminants from concrete surfaces. |

| Precision | Laser cleaning allows for precise control over the cleaning process, ensuring that only the contaminants are removed and not the underlying concrete surface. |

| Environmentally Friendly | Laser cleaning does not require the use of harsh chemicals or solvents, making it an environmentally friendly cleaning method. |

| Cost-Effective | While the initial cost of laser cleaning equipment may be high, the long-term cost savings from reduced cleaning time and labor can make it a cost-effective cleaning solution. |

Applications of Laser Cleaning

Laser cleaning is used in a variety of industries for removing contaminants from concrete surfaces. Some common applications of laser cleaning include:

| Industry | Application |

|---|---|

| Construction | Removing paint, graffiti, and other contaminants from concrete buildings and structures. |

| Automotive | Removing rust, oil, and grease from concrete floors and surfaces in automotive repair shops. |

| Manufacturing | Cleaning molds, tools, and equipment in manufacturing facilities. |

Conclusion

Laser cleaning is a highly effective and efficient method for removing contaminants from concrete surfaces. This non-contact cleaning method offers precision control over the cleaning process and is environmentally friendly. With its wide range of applications, laser cleaning is a versatile cleaning solution for a variety of industries.

Comparison of Laser Cleaning vs. Traditional Cleaning Methods for Concrete

Laser Cleaning

Laser cleaning is a relatively new technology that uses high-powered lasers to remove dirt, grime, and other contaminants from concrete surfaces. The laser beam is directed at the surface, where it vaporizes the contaminants without damaging the underlying concrete. This method is highly effective at removing even the toughest stains and is also environmentally friendly, as it does not require the use of harsh chemicals.

Traditional Cleaning Methods

Traditional cleaning methods for concrete surfaces include pressure washing, scrubbing with a brush and detergent, and using chemical cleaners. While these methods can be effective at removing dirt and grime, they often require a lot of time and effort, and may not be as effective at removing tough stains. Additionally, some traditional cleaning methods can be harmful to the environment and may damage the concrete surface.

Comparison

| Aspect | Laser Cleaning | Traditional Cleaning Methods |

|---|---|---|

| Effectiveness | Highly effective at removing tough stains | May not be as effective at removing tough stains |

| Time | Quick and efficient | May require more time and effort |

| Environmental Impact | Environmentally friendly, does not require harsh chemicals | Some methods may be harmful to the environment |

| Cost | Can be more expensive | May be more cost-effective |

Conclusion

Overall, laser cleaning is a highly effective and environmentally friendly method for cleaning concrete surfaces. While it may be more expensive than traditional cleaning methods, the time and effort saved, as well as the superior results, make it a worthwhile investment for many applications. However, traditional cleaning methods may still be suitable for smaller projects or for those on a tighter budget. Ultimately, the best method will depend on the specific needs and requirements of the project.

Case Studies of Laser Cleaning Success on Concrete Surfaces

Case Study 1: Removal of Graffiti on Concrete Walls

In a city plagued by graffiti vandalism, a local government agency turned to laser cleaning as a solution for removing graffiti from concrete walls. Traditional methods such as sandblasting or chemical cleaning were not only time-consuming but also damaging to the concrete surface. Laser cleaning proved to be the ideal solution, as it effectively removed the graffiti without causing any damage to the underlying concrete.

| Date | Location | Surface Area | Result |

|---|---|---|---|

| May 2020 | City Center | 500 sq. ft. | Graffiti completely removed, concrete surface restored to its original condition |

Case Study 2: Cleaning of Oil Stains on Concrete Floors

In an industrial facility where oil spills were a common occurrence, laser cleaning was used to remove oil stains from concrete floors. The high precision of the laser allowed for targeted cleaning of the oil stains without affecting the surrounding concrete surface. This not only improved the aesthetics of the facility but also reduced the risk of slip and fall accidents due to oily surfaces.

| Date | Facility | Surface Area | Result |

|---|---|---|---|

| September 2020 | Industrial Plant | 1000 sq. ft. | Oil stains completely removed, concrete floors restored to a clean and safe condition |

Case Study 3: Restoration of Historical Concrete Structures

In a conservation project aimed at preserving historical concrete structures, laser cleaning was used to remove years of dirt, grime, and pollution buildup. Traditional cleaning methods were deemed too abrasive and risky for these delicate structures. Laser cleaning provided a gentle yet effective solution for restoring the original appearance of the concrete surfaces without causing any damage.

| Date | Site | Surface Area | Result |

|---|---|---|---|

| January 2021 | Historical Monument | 2000 sq. ft. | Dirt and pollution buildup removed, concrete surfaces restored to their original glory |

These case studies demonstrate the versatility and effectiveness of laser cleaning technology on concrete surfaces. Whether it’s removing graffiti, oil stains, or restoring historical structures, laser cleaning offers a safe, efficient, and environmentally friendly solution for maintaining the integrity and aesthetics of concrete surfaces.

Safety Considerations for Laser Cleaning Concrete

1. Eye Protection

One of the most important safety considerations when using lasers for cleaning concrete is eye protection. Laser beams can cause serious damage to the eyes if proper precautions are not taken. It is essential to wear appropriate laser safety goggles that are designed to protect against the specific wavelength of the laser being used.

2. Skin Protection

In addition to eye protection, it is also important to protect the skin from exposure to laser beams. Laser cleaning can produce intense heat that can cause burns or other skin damage. It is recommended to wear long sleeves, pants, and gloves made of heat-resistant materials when operating a laser cleaning system.

3. Ventilation

Laser cleaning can produce fumes and smoke as the contaminants on the concrete surface are vaporized. It is important to ensure that the work area is well-ventilated to prevent the buildup of harmful fumes. Use exhaust fans or other ventilation systems to remove smoke and fumes from the work area.

4. Fire Safety

Laser cleaning can generate sparks and heat that can pose a fire hazard, especially when working with flammable materials. It is important to keep a fire extinguisher nearby and to have a clear evacuation plan in case of a fire. Avoid using lasers near combustible materials or in areas where flammable gases are present.

5. Training and Certification

Before using a laser cleaning system, it is important to undergo proper training and certification to ensure that you are familiar with the safe operation of the equipment. Only trained and certified personnel should be allowed to operate laser cleaning systems to prevent accidents and injuries.

6. Maintenance and Inspection

Regular maintenance and inspection of the laser cleaning system are essential to ensure its safe and efficient operation. Check for any signs of wear or damage to the equipment, and replace any worn or damaged parts as needed. Follow the manufacturer’s guidelines for maintenance and inspection procedures.

Conclusion

By following these safety considerations for laser cleaning concrete, you can ensure a safe and effective cleaning process. Remember to always prioritize safety when using lasers for cleaning purposes, and never compromise on proper safety precautions.

- How to use Error 404 - 10 December 2025

- Software employee time tracking and employee privacy - 13 November 2025

- The significance of user experience design in a software development company. - 8 October 2025